Arc Flash Hazard Analysis

What is Arc Flash?

Arc Flash is the result of a rapid release of energy due to an arcing fault between a phase bus bar and another phase bus bar, neutral or a ground. During an arc fault the air is the conductor. Arc faults are generally limited to systems where the bus voltage is in excess of 120 volts. Lower voltage levels normally will not sustain an arc. An arc fault is similar to the arc obtained during a welding and the fault has to be manually started by something creating the path of conduction or a failure such as a breakdown in insulation.

The cause of the short normally burns away during the initial flash and the arc fault is then sustained by the establishment of highly-conductive plasma. The plasma will conduct as much energy as is available and is only limited by the impedance of the arc. This massive energy discharge burns the bus bars, vaporizing the copper and thus causing an explosive volumetric increase, the arc blast. This fiery explosion devastates everything in its path, creating deadly shrapnel as it dissipates.

Six Steps to Implementing an Arc Flash Safety Program:

Step No. 1 - The Flash Analysis

The National Fire Protection Association, States in NFPA 70E, Article 130.3: “A flash hazard analysis shall be done in order to protect personnel from the possibility of being injured by an arc flash. The analysis shall determine the flash protection boundary and the personal protective equipment that people within the flash boundary shall use.”

Step No. 2 – Gather the Information

The next step is to gather the information needed to perform the calculations. Several pieces of information are required, including:

- Available short circuit current at the point of contact

- Nominal voltage

- Maximum total clearing time of the protective devices

- Working Distance

- Type of Protective Device (including model numbers and settings)

- Type of Conductors, Conductor Size, and Their Lengths

The information gathered above will provide you with an accurate and detailed one line building power drawing. The one-line drawings provided will be a useful tool in managing your power distribution system with future projects and help with engineering ways to reduce the exposure of incident energy to the workers. We use the latest software from SKM Power Tools and ESA to perform these studies.

Step No. 3 – Perform an Arc Flash Study

This third step calculates the incident energy that would be received by the worker at the point of contact. This incident energy provided by the study will be given in calories/cm2. Incident energy is defined in NFPA 70E as “the amount of energy impressed on a surface, a certain distance from the source, generated during an electrical arc event. One of the units measured incident energy is calories per centimeter squared (cal/cm2).”

Step No. 4 – Choose the Proper PPE

The PPE is critical to protecting the worker from injury. After the arc flash study is performed, the cal/cm2 derived must be compared with the PPE being considered. Implementing the recommendation will help protect your workers and help you satisfy OSHA requirements.

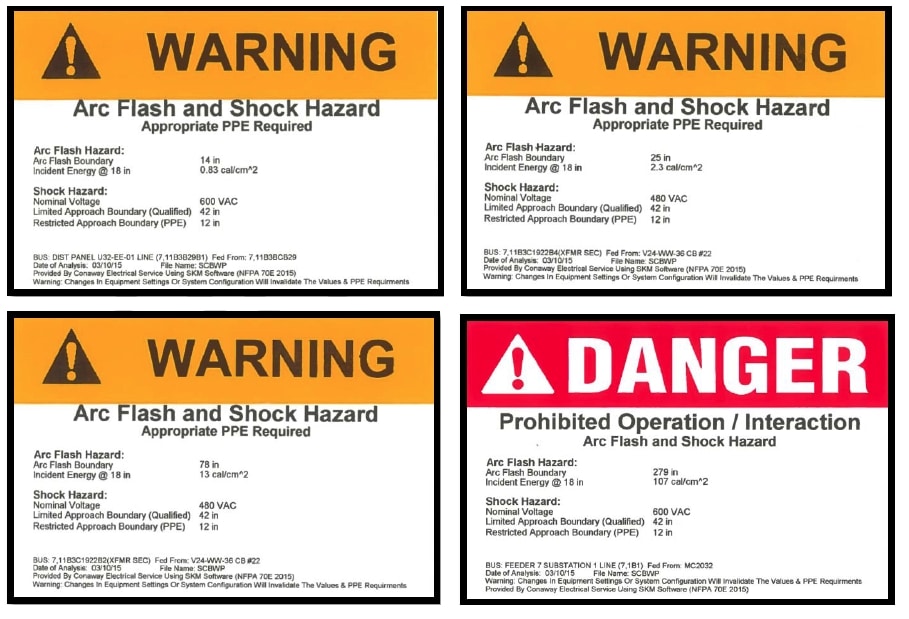

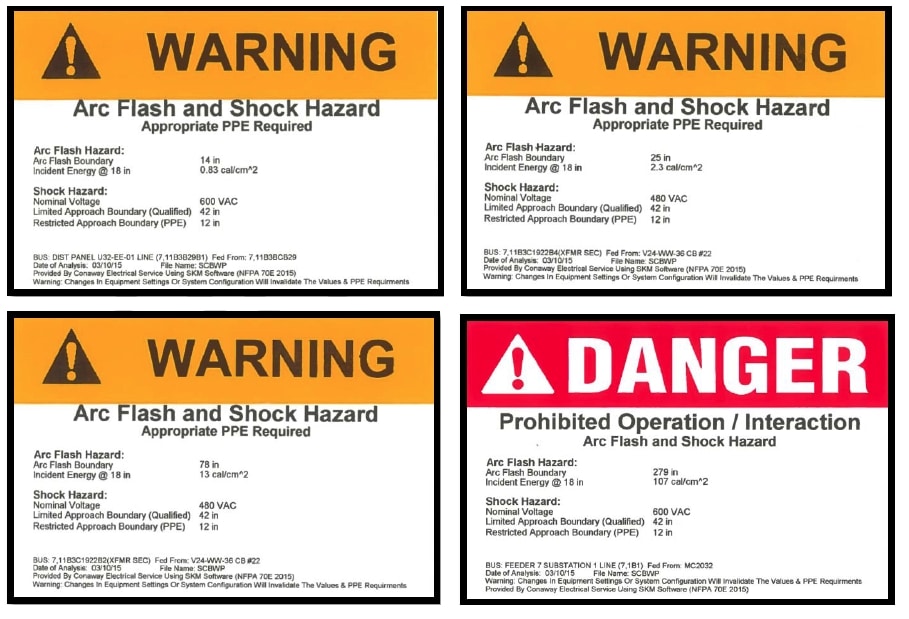

Step No. 5 – Label the Equipment

NFPA 70E labeling requirements include placing a label on the equipment informing the worker of the flash protection boundary, incident energy, working distance, required PPE level, and the shock hazard voltage and boundaries. Labels must be made up from the results of the flash hazard analysis and attached to the electrical equipment.

Step No. 6 – Train Your Workers

OSHA and NFPA 70E require that workers be qualified in order to work on or near energized electrical systems. In order for the arc flash study to be effective, workers must be trained in what the labeling means and how to apply the information on the equipment. One of the first things OSHA does during a site inspection or an accident investigation is to review the training records for the company. Lack of training often results into large fines. At least two training programs should be given, one for the supervisory personnel and one for the front line workers.

Conclusion

Arc Flash Analysis is actually Risk Management. There are basically three choices:

- Be very conservative and require Category 4 PPE in most cases resulting in higher maintenance cost.

- Do nothing and suffer the consequences (pay later).

- Perform the necessary analysis and make adjustments to reduce the arc flash conditions resulting in reduced PPE requirements.

Conaway Electrical can provide your company with the resources it needs to implement an Arc Flash Safety Program. This program will increase the understanding and awareness of electrical hazards, minimize the risk of exposure and consequently avoid injury to individuals who work on or near electrical equipment.